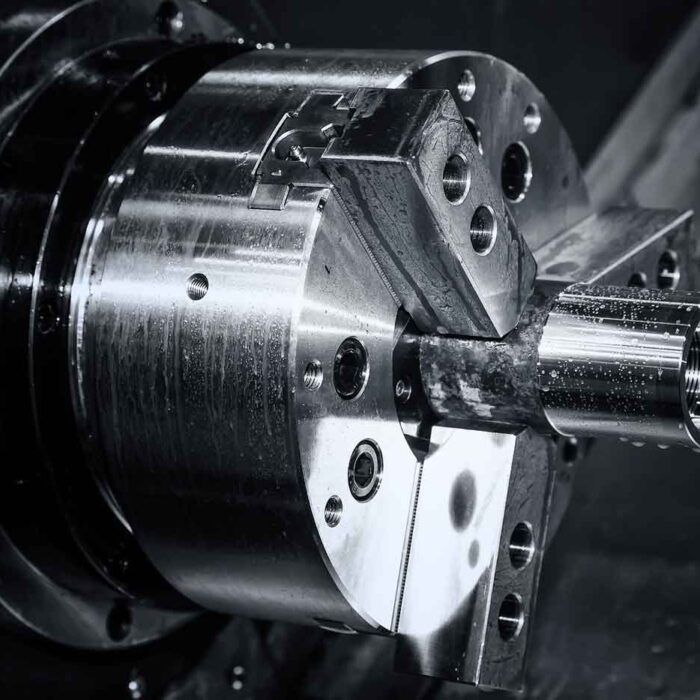

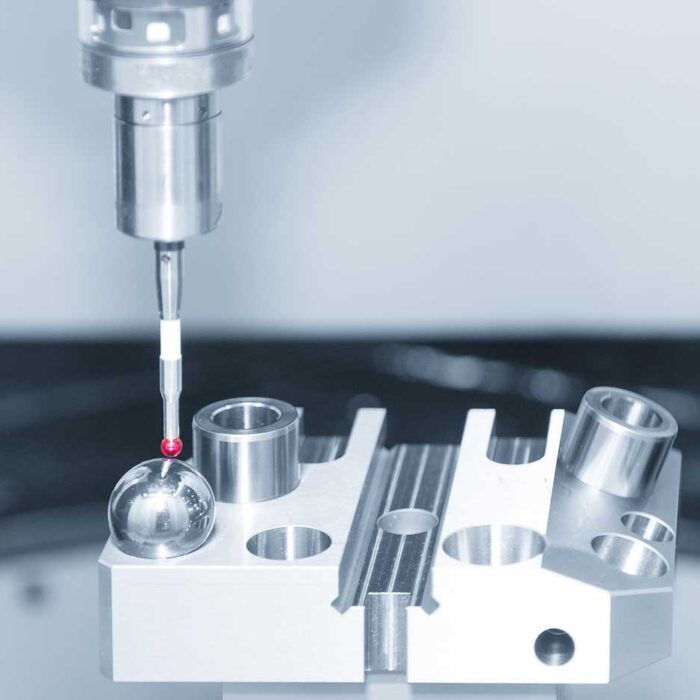

Manufacturing and Procurement of oilfield materials, components, and systems is part of Seahorse Energy’s® DNA. We have experience in practically every form of manufacturing required in the Oil and Gas industry. From fabrication to advanced CNC CAD/CAM nine-axis milling, Seahorse Energy® has the experience and expertise to manufacture components using well-established quality control processes. Examples include:

- Piping and tubing sourcing

- All forms of lathe and milling work

- Water jetting, saw cutting, laser cutting, and grinding

- Full fabrication of structures

- Full cladding to API/ISO NACE standards

- Metallurgical services

- Tensile, hardness, bending, impact, NACE

- Metallurgical and chemical analyses

- Fatigue, fracture mechanics, CTOD

- Full inspection/NDE services

- CMM and manual dimensional inspection

- Hardness

- MPI

- PMI

- LPI

- RT

- Visual

- UT

- Equipment maintenance and refurbishment

- Clean up

- Inspection/NDE

- Re-coating

- Repairs

- Clad repairs

- Creation of manufacturing drawings strictly to ASME Y14.5 2009 drafting standards

- Machining, welding, and fabricating to third-party drawings

- Experience with all industry coatings

- Fluoropolymer

- Moly-disulfide

- Phosphate

- Plating (silver, gold, etc.)

- Hard-facing (tungsten-carbide, chrome)

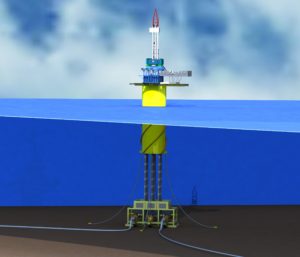

The team at Seahorse Energy® has experience in the development of critical dry tree production system components. These components range from high pressure drilling risers to tieback connectors. Also unique to Seahorse Energy®, the team has experience in the specification, design, and manufacturing of carbon-fiber production risers, drilling risers, and choke and kill lines. The team also has experience designing stress joints made of both steel and titanium.

The team at Seahorse Energy® has experience in the development of critical dry tree production system components. These components range from high pressure drilling risers to tieback connectors. Also unique to Seahorse Energy®, the team has experience in the specification, design, and manufacturing of carbon-fiber production risers, drilling risers, and choke and kill lines. The team also has experience designing stress joints made of both steel and titanium. Having the right people offshore makes all the difference in the world. Seahorse Energy® field service and engineering personnel have the experience to make it happen offshore — safely and reliably. Whether it is running new equipment or repeat equipment, our team is ready to support you. We have experience organizing and leading WOPs of many varieties which is key to safe and cost efficient offshore operations.

Having the right people offshore makes all the difference in the world. Seahorse Energy® field service and engineering personnel have the experience to make it happen offshore — safely and reliably. Whether it is running new equipment or repeat equipment, our team is ready to support you. We have experience organizing and leading WOPs of many varieties which is key to safe and cost efficient offshore operations. The Seahorse Energy® team has experience supporting many types of offshore operations including intervention. Subsea interventions require experienced people that can think quick on their feet, but remain disciplined in approach under all situations. The Seahorse Energy® team has this experience and is ready to assist you during the planning stage and on your next offshore intervention.

The Seahorse Energy® team has experience supporting many types of offshore operations including intervention. Subsea interventions require experienced people that can think quick on their feet, but remain disciplined in approach under all situations. The Seahorse Energy® team has this experience and is ready to assist you during the planning stage and on your next offshore intervention. Drilling operations are key to successful subsea operations in the short and long term. The Seahorse Energy® team has decades of drilling and pressure containment experience. This experience ranges from both low and high pressure drilling riser systems (diverters, telescopic joints, choke and kill lines, aux lines, risers joints and connectors, etc.). This experience includes both conventional materials and carbon fiber composites.

Drilling operations are key to successful subsea operations in the short and long term. The Seahorse Energy® team has decades of drilling and pressure containment experience. This experience ranges from both low and high pressure drilling riser systems (diverters, telescopic joints, choke and kill lines, aux lines, risers joints and connectors, etc.). This experience includes both conventional materials and carbon fiber composites. Keeping a subsea system profitable usually requires an occasional intervention to improve productivity. Seahorse Energy® has a broad range of experience in engineering and manufacturing of intervention equipment. Recent experience led to the deepest riser-less intervention in the world. Some of this experience includes:

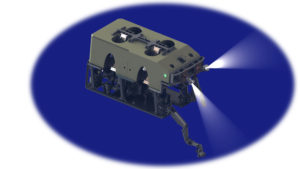

Keeping a subsea system profitable usually requires an occasional intervention to improve productivity. Seahorse Energy® has a broad range of experience in engineering and manufacturing of intervention equipment. Recent experience led to the deepest riser-less intervention in the world. Some of this experience includes: Having the proper ROV tooling and technology is essential for a successful subsea development. Seahorse Energy® has significant experience designing and building ROV tooling and equipment that do remarkable things subsea. We can also design and manufacture very quickly new solutions for those “unexpected” situations where innovation and speed is required to meet an unplanned challenge. A few examples are:

Having the proper ROV tooling and technology is essential for a successful subsea development. Seahorse Energy® has significant experience designing and building ROV tooling and equipment that do remarkable things subsea. We can also design and manufacture very quickly new solutions for those “unexpected” situations where innovation and speed is required to meet an unplanned challenge. A few examples are: Subsea trees come in many forms, sizes, and capabilities. At Seahorse Energy®, we understand and have the experience to design, manufacture, and integrate subsea production components. We have experience in HPHT applications, as the engineers at Seahorse Energy® were involved in the implementation of the world’s first 15K horizontal tree systems years ago. Seahorse Energy® has critical metal-to-metal seal design, analysis, and testing experience for high-pressure and high-temperature applications. Seahorse Energy® personnel have pioneering developmental and implementation experience in some of the first 20KSI seal systems for subsea use. We have the ability to develop testing and SIT procedures and/or manage your entire SIT.

Subsea trees come in many forms, sizes, and capabilities. At Seahorse Energy®, we understand and have the experience to design, manufacture, and integrate subsea production components. We have experience in HPHT applications, as the engineers at Seahorse Energy® were involved in the implementation of the world’s first 15K horizontal tree systems years ago. Seahorse Energy® has critical metal-to-metal seal design, analysis, and testing experience for high-pressure and high-temperature applications. Seahorse Energy® personnel have pioneering developmental and implementation experience in some of the first 20KSI seal systems for subsea use. We have the ability to develop testing and SIT procedures and/or manage your entire SIT. The team at Seahorse Energy® has a vast amount of experience in developing, manufacturing, and installing subsea jumper systems and the related connector systems. We can also manage your jumper metrology, SITs, and installations. We have experience in developing and manufacturing the following connection systems:

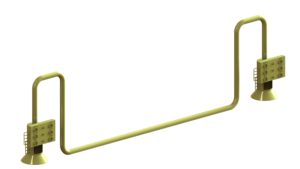

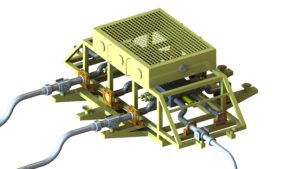

The team at Seahorse Energy® has a vast amount of experience in developing, manufacturing, and installing subsea jumper systems and the related connector systems. We can also manage your jumper metrology, SITs, and installations. We have experience in developing and manufacturing the following connection systems: At the heart of a subsea production system is the ability to reliably and safely connect the various infrastructures as the field architecture progresses. The Seahorse team has the experience to design, manage, and manufacture subsea templates, manifolds, horizontal and vertical connection systems, manifold piping and valving. We also have experience developing FAT/SIT procedures and managing the testing.

At the heart of a subsea production system is the ability to reliably and safely connect the various infrastructures as the field architecture progresses. The Seahorse team has the experience to design, manage, and manufacture subsea templates, manifolds, horizontal and vertical connection systems, manifold piping and valving. We also have experience developing FAT/SIT procedures and managing the testing.