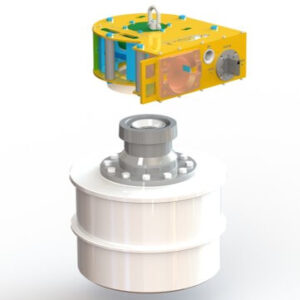

Knock-On Cap

After removing a subsea tree from its manifold, protection is needed for the manifold piping, valves and seal surfaces for long-term preservation. Seahorse Energy® engineered, manufactured and tested a new pressure cap (Knock-On Cap) to meet these needs – and this was done in 11 weeks. The pressure rating was 5,000 psi for each passageway in the multi-bore hub, and the nominal connector size was 18”. The resulting pressure end loads were over 400,000 pounds. Because of this, it was critical for the design to be efficient and light weight. The Knock-On Cap is a great example of the connector expertise that exists at Seahorse Energy®.

Pompano Subsea Connection System Connector

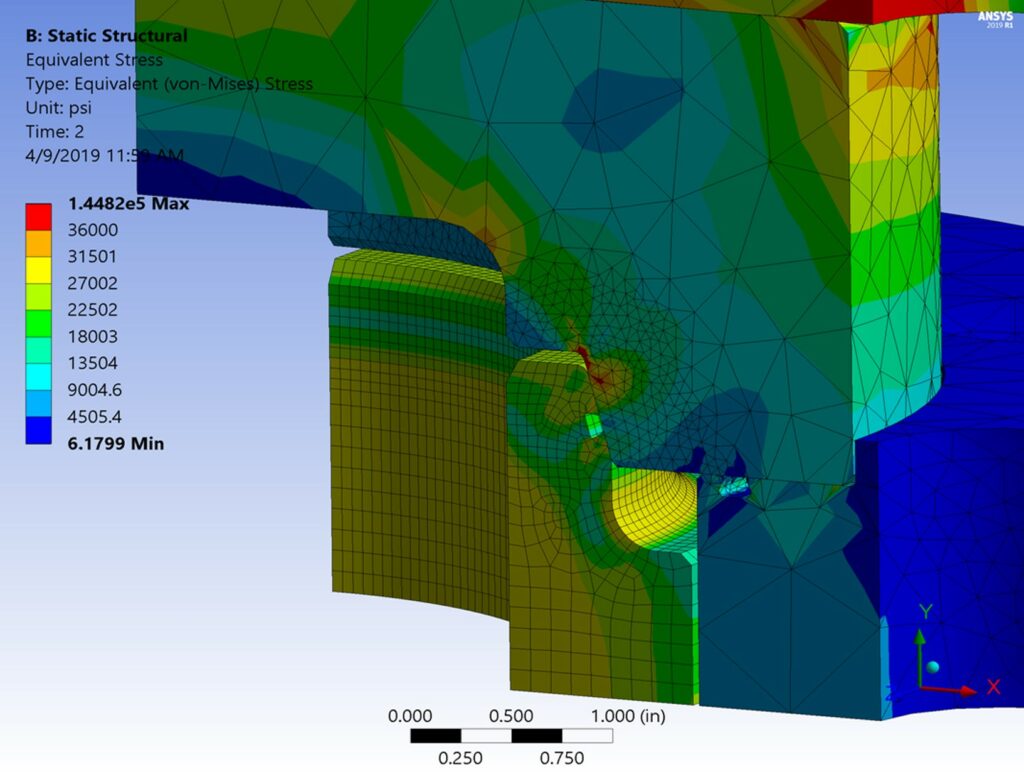

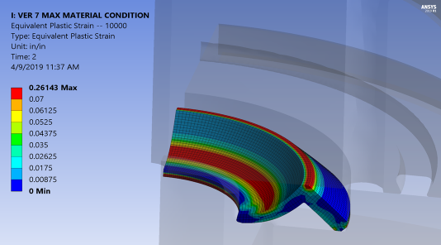

The Pompano project uses a unique subsea connection with a multi-bore horizontal connection system. The main elements to the system are 2 hubs, a connector and the special running tool. The connector is made up of a clamp and a seal plate. The purpose of the running tool is to pull the 2 hubs together, “sandwiching” the seal plate and clamp between them. Then, the running tool is used to torque the 2 drive screws on the clamp, which preloads the system. For this project, a new connector was needed(seal plate and clamp). Seahorse Energy® engineered, manufactured and tested a new connector for the Pompano subsea tieback.

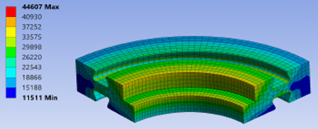

SEI V-Seal System

New seals were needed for the seal plate associated with the Troika Jumper end kit (see associated project description). These included V-seals (metal-to-metal and elastomer) as well as a production bore seal. Seahorse Energy® engineered, manufactured and tested new seals to function in the existing customer property geometry. Because of extensive sealing experience, Seahorse has successfully developed these new seals in a fraction of the time of a traditional new seal delivery (weeks vs. months).

The team at Seahorse Energy® has experience in the development of critical dry tree production system components. These components range from high pressure drilling risers to tieback connectors. Also unique to Seahorse Energy®, the team has experience in the specification, design, and manufacturing of carbon-fiber production risers, drilling risers, and choke and kill lines. The team also has experience designing stress joints made of both steel and titanium.

The team at Seahorse Energy® has experience in the development of critical dry tree production system components. These components range from high pressure drilling risers to tieback connectors. Also unique to Seahorse Energy®, the team has experience in the specification, design, and manufacturing of carbon-fiber production risers, drilling risers, and choke and kill lines. The team also has experience designing stress joints made of both steel and titanium. Having the right people offshore makes all the difference in the world. Seahorse Energy® field service and engineering personnel have the experience to make it happen offshore — safely and reliably. Whether it is running new equipment or repeat equipment, our team is ready to support you. We have experience organizing and leading WOPs of many varieties which is key to safe and cost efficient offshore operations.

Having the right people offshore makes all the difference in the world. Seahorse Energy® field service and engineering personnel have the experience to make it happen offshore — safely and reliably. Whether it is running new equipment or repeat equipment, our team is ready to support you. We have experience organizing and leading WOPs of many varieties which is key to safe and cost efficient offshore operations. The Seahorse Energy® team has experience supporting many types of offshore operations including intervention. Subsea interventions require experienced people that can think quick on their feet, but remain disciplined in approach under all situations. The Seahorse Energy® team has this experience and is ready to assist you during the planning stage and on your next offshore intervention.

The Seahorse Energy® team has experience supporting many types of offshore operations including intervention. Subsea interventions require experienced people that can think quick on their feet, but remain disciplined in approach under all situations. The Seahorse Energy® team has this experience and is ready to assist you during the planning stage and on your next offshore intervention. Drilling operations are key to successful subsea operations in the short and long term. The Seahorse Energy® team has decades of drilling and pressure containment experience. This experience ranges from both low and high pressure drilling riser systems (diverters, telescopic joints, choke and kill lines, aux lines, risers joints and connectors, etc.). This experience includes both conventional materials and carbon fiber composites.

Drilling operations are key to successful subsea operations in the short and long term. The Seahorse Energy® team has decades of drilling and pressure containment experience. This experience ranges from both low and high pressure drilling riser systems (diverters, telescopic joints, choke and kill lines, aux lines, risers joints and connectors, etc.). This experience includes both conventional materials and carbon fiber composites. Keeping a subsea system profitable usually requires an occasional intervention to improve productivity. Seahorse Energy® has a broad range of experience in engineering and manufacturing of intervention equipment. Recent experience led to the deepest riser-less intervention in the world. Some of this experience includes:

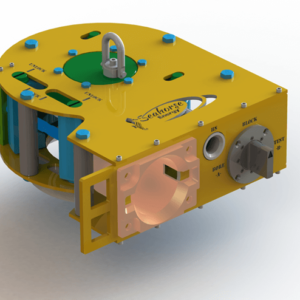

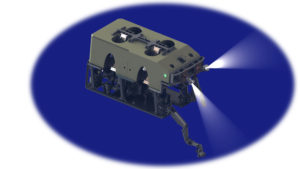

Keeping a subsea system profitable usually requires an occasional intervention to improve productivity. Seahorse Energy® has a broad range of experience in engineering and manufacturing of intervention equipment. Recent experience led to the deepest riser-less intervention in the world. Some of this experience includes: Having the proper ROV tooling and technology is essential for a successful subsea development. Seahorse Energy® has significant experience designing and building ROV tooling and equipment that do remarkable things subsea. We can also design and manufacture very quickly new solutions for those “unexpected” situations where innovation and speed is required to meet an unplanned challenge. A few examples are:

Having the proper ROV tooling and technology is essential for a successful subsea development. Seahorse Energy® has significant experience designing and building ROV tooling and equipment that do remarkable things subsea. We can also design and manufacture very quickly new solutions for those “unexpected” situations where innovation and speed is required to meet an unplanned challenge. A few examples are: Subsea trees come in many forms, sizes, and capabilities. At Seahorse Energy®, we understand and have the experience to design, manufacture, and integrate subsea production components. We have experience in HPHT applications, as the engineers at Seahorse Energy® were involved in the implementation of the world’s first 15K horizontal tree systems years ago. Seahorse Energy® has critical metal-to-metal seal design, analysis, and testing experience for high-pressure and high-temperature applications. Seahorse Energy® personnel have pioneering developmental and implementation experience in some of the first 20KSI seal systems for subsea use. We have the ability to develop testing and SIT procedures and/or manage your entire SIT.

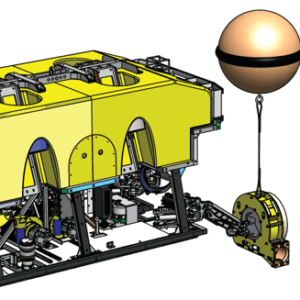

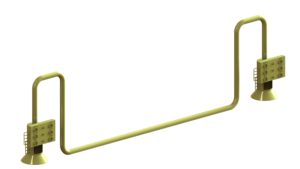

Subsea trees come in many forms, sizes, and capabilities. At Seahorse Energy®, we understand and have the experience to design, manufacture, and integrate subsea production components. We have experience in HPHT applications, as the engineers at Seahorse Energy® were involved in the implementation of the world’s first 15K horizontal tree systems years ago. Seahorse Energy® has critical metal-to-metal seal design, analysis, and testing experience for high-pressure and high-temperature applications. Seahorse Energy® personnel have pioneering developmental and implementation experience in some of the first 20KSI seal systems for subsea use. We have the ability to develop testing and SIT procedures and/or manage your entire SIT. The team at Seahorse Energy® has a vast amount of experience in developing, manufacturing, and installing subsea jumper systems and the related connector systems. We can also manage your jumper metrology, SITs, and installations. We have experience in developing and manufacturing the following connection systems:

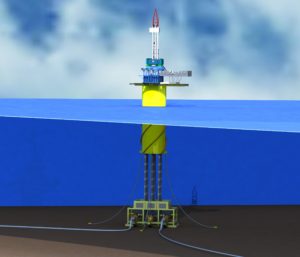

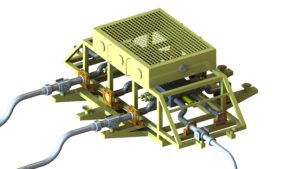

The team at Seahorse Energy® has a vast amount of experience in developing, manufacturing, and installing subsea jumper systems and the related connector systems. We can also manage your jumper metrology, SITs, and installations. We have experience in developing and manufacturing the following connection systems: At the heart of a subsea production system is the ability to reliably and safely connect the various infrastructures as the field architecture progresses. The Seahorse team has the experience to design, manage, and manufacture subsea templates, manifolds, horizontal and vertical connection systems, manifold piping and valving. We also have experience developing FAT/SIT procedures and managing the testing.

At the heart of a subsea production system is the ability to reliably and safely connect the various infrastructures as the field architecture progresses. The Seahorse team has the experience to design, manage, and manufacture subsea templates, manifolds, horizontal and vertical connection systems, manifold piping and valving. We also have experience developing FAT/SIT procedures and managing the testing.